VFE Contact

The Science of Vacuum Brazing: Ensuring Strength, Reliability, and Performance in Joint Design

The Science of Vacuum Brazing: Ensuring Strength, Reliability, and Performance in Joint Design

In manufacturing, many applications require the joining of parts where joint geometry prohibits direct access. In such applications, brazing is often used because it allows joints to be fused together without needing direct access to the joint surfaces. This technique is particularly valuable in industries such as aerospace, medical devices, nuclear, and defence, where components can have complex geometries. The criticality of these applications requires components to be reliable under harsh conditions, such as high temperatures, while maintaining minimal distortion and stress to preserve dimensional and functional integrity. Vacuum brazing provides the optimal conditions for producing highly reliable joints in these demanding applications.

VFE has over 34 years of experience in the furnace industry which having installed, serviced, or optimized more than 60 brazing furnaces. Joint design is crucial for ensuring reliability, but even well-designed joints can fail if the correct joining techniques and specifications are not followed.

This article explores vacuum brazing, how it works, and the key design considerations for vacuum brazing furnaces, including control systems and instrumentation necessary to create the right atmosphere for the process, ensuring joint integrity.

Understanding vacuum brazing

Vacuum brazing is a unique, flux-less process of joining two or more metals, ceramics, or even metals to ceramics. Typically, a filler metal is used, which can be in the form of a metal preform, wire, or paste. Metal alloys can also be used instead of pure metals, with eutectic alloys being particularly effective for brazing since they co-exist at the eutectic temperature and behave similarly to pure metals. The vacuum brazing process can occur under complete vacuum, partial pressure, or even ultra-high vacuum environments, achieving a clean, bright, and oxide-free finish.

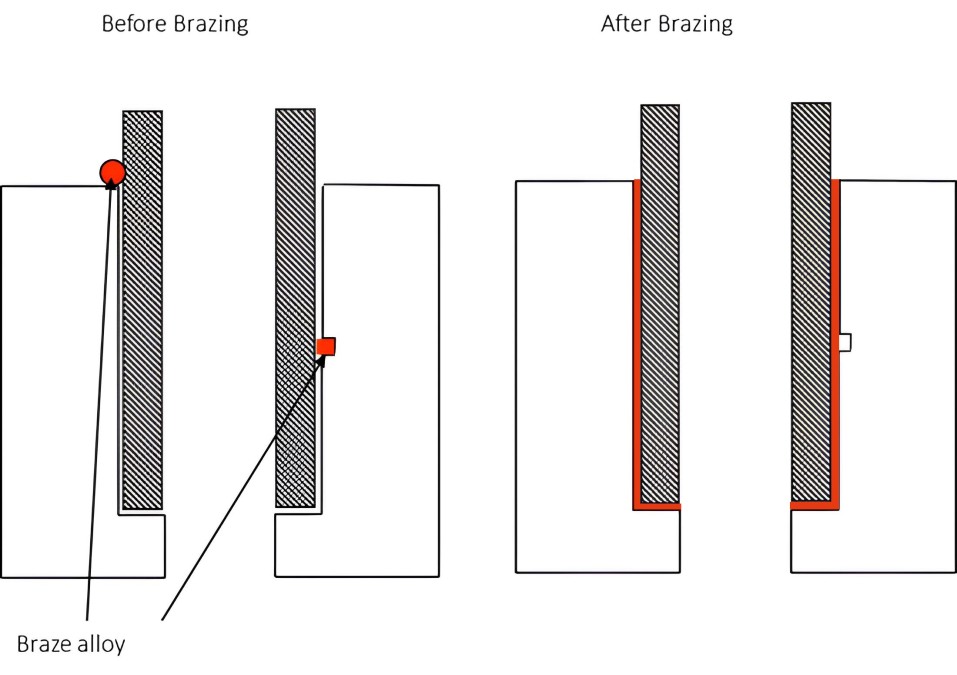

The filler metal, having a lower melting point than the adjoining metals, melts and flows into the joint, where it then solidifies to create a bond. When it becomes a liquid, the filler reaches a temperature at which its surface tension is lower, allowing it to wet a greater surface area and fill the joint correctly. The liquid spreads by capillary action within the joint cavity between the metals, creating an intermediate layer, as illustrated in Figure 1 below.

Obtaining the right joint tolerances is critical for successful vacuum brazing. The gap must be neither too small, making the bond difficult to fill, nor too large, which could result in a weak joint with gaps or porosity.

As the brazing alloy or filler melts at a lower temperature than the substrate (the metals being joined), the mechanical properties of the substrate are not adversely affected. A perfectly brazed joint requires a clean surface, oxide free, without traces of processing oils or greases, to ensure good wettability. This allows the alloy or filler to be drawn onto the surfaces to be joined.

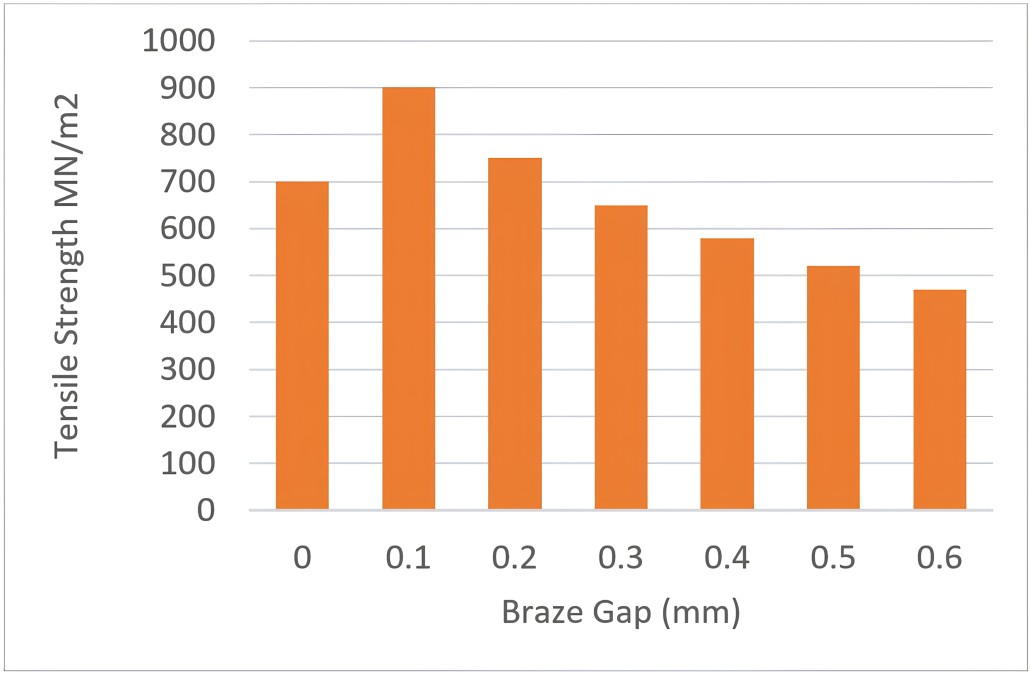

To achieve a high-quality brazed bond with properties such as stress resistance and corrosion resistance, it is essential to create a highly controlled environment. For maximum joint strength, the gap clearance should be as parallel as possible, with the gap between mating surfaces held within 0.03 - 0.08mm at brazing temperature (which may vary depending on the alloy used). The chart provided below illustrates the relationship between braze gap and the tensile strength of a joint.

Why vacuum brazing?

Vacuum brazing is crucial for joining components where high joint strength and flawless quality are required, especially in critical applications. Several factors highlight how a vacuum environment contributes to creating strong, high-quality joints:

Elimination of oxidation

In a vacuum environment, the absence of air (and thus oxygen) prevents the formation of oxides on metal surfaces. Oxides can act as barriers to the wetting and bonding process, weakening the joint. By eliminating oxidation, the metal surfaces remain clean and free of contaminants, ensuring better adhesion of the filler metal.

Enhanced wetting and capillary action

The vacuum environment reduces surface tension and promotes better capillary action of the molten filler metal, allowing it to flow more smoothly and cover the joint area completely thus enhancing wettability. This improved wetting enables the filler metal to penetrate microscopic gaps and irregularities in the joint area, resulting in a more uniform and stronger bond.

Removal of volatiles and contaminants

The vacuum environment helps remove volatile substances and contaminants that may be present on the metal surfaces or within the filler material. This outgassing process ensures that the joint area remains clean and free from impurities.

Enhancing temperature uniformity

Vacuum brazing ensures even heating of the components and the filler metal. This uniform temperature distribution helps form a homogeneous alloy at the joint, resulting in consistent mechanical properties across the entire bond. This consistency ensures no weak spots, contributing to the overall strength and reliability of the brazed component.

Minimisation of residual stresses

The vacuum furnace allows for controlled cooling rates, minimizing the development of residual stresses within the joint. Residual stresses can lead to cracking or weakening of the joint over time. By carefully controlling the cooling process, vacuum brazing produces joints that are more stable and durable under operational conditions.

High purity environment

While vacuum brazing primarily uses a vacuum to achieve these benefits, sometimes an inert gas like argon or a reducing gas like hydrogen may be introduced at low pressures. This further enhances the purity of the environment, especially for metals that are highly reactive. Design considerations of vacuum furnace

To successfully achieve the enhanced brazing capabilities using vacuum, it is imperative to use the right vacuum furnace equipment. The following design factors should be considered while selecting a vacuum furnace for your process.

Cleanliness

The hot zone of a vacuum furnace can be constructed with either graphite insulation or multiple layers of metal reflective shielding, such as molybdenum/lanthanum for the internal shields, molybdenum for the intermediate shields, and stainless steel for the external shields. The selection is determined by the required vacuum level for brazing the specific workpiece and whether it reacts with carbon, ultimately ensuring a clean brazing environment.

Temperature

The hot zone can reach operating temperatures ranging from 650 °C for brazing aluminium components to 2200 °C for ceramics and more exotic materials. High-temperature refractory metals such as molybdenum are used to construct the hot zone, allowing it to reach temperatures between 900 °C and 1400 °C. For even higher temperatures, tungsten is employed, accommodating ranges from 1500 °C to 2200 °C.

The development of high-purity carbon fibre insulation has made graphite hot zone construction more common in 90% of applications, covering the temperature range of 900 °C to 2200 °C. Graphite is a more thermally efficient insulating material, so if the workpiece does not react with carbon and a vacuum of 1x10-5 mbar or greater is not required, graphite is often chosen. This preference is due to its energy savings and ease of maintenance compared to an all-metal hot zone.

Temperature uniformity

The hot zone heating must be controllable with the ability to fine-tune the temperature as required. Maintaining uniform heat in the chamber is crucial for vacuum brazing. Typically, vacuum furnaces should not vary by more than 5 °C from the set temperature in either direction, and in some cases, a variance of only 3 oC is required to minimize distortion or to comply with the Aerospace Material Specification AMS2750 rev G.

Vacuum

The ability to create and maintain a high vacuum in the vacuum furnace is crucial for successful brazing. Three stages of pumping are utilized to ensure a high vacuum is maintained during furnace operation.

The initial vacuum stages are achieved using mechanical pumps, reaching a vacuum level in the range of 10-2 to 10-3 mbar. The first stage typically involves a rotary vane vacuum pump or a dry, oil-free screw vacuum pump. The second stage usually employs a positive displacement rotary lobe pump, known as a roots booster pump. To reach the desired operating vacuum level for brazing, an oil vapor diffusion pump is used, typically achieving a vacuum level of 10-5 mbar.

Additional enhancements to the vacuum system can be implemented, such as incorporating a hot water system in the furnace chamber to remove moisture from surfaces and improve the vacuum level. Alternatively, a cryogenic baffle can be added to trap moisture and further improve the ultimate vacuum. Additionally, the cryogenic baffle can reduce chamber pump down time by up to 75%.

Hydrogen

The use of hydrogen is significant due to its ability to actively remove oxides from metal surfaces, ensuring clean and oxide-free interfaces necessary for a strong joint. Vacuum furnaces can be designed to introduce either a small bleed of hydrogen at partial pressure (0.1-1 mbar abs) or a full reducing atmosphere of hydrogen (1 bar abs) to improve brazing quality.

Once the right vacuum furnace is selected based on the design considerations discussed above, it is essential to have a control system that is user-friendly and tailored to the process requirements, along with a set of properly calibrated instruments. Process control becomes a mandatory requirement to create the right environment for brazing and to ensure that the process recipe is followed accurately.

Is your vacuum furnace optimized for precision brazing? Our experts can assess its performance, recommend improvements, and implement the necessary upgrades or maintenance.

Contact us today.

Controls and instrumentation

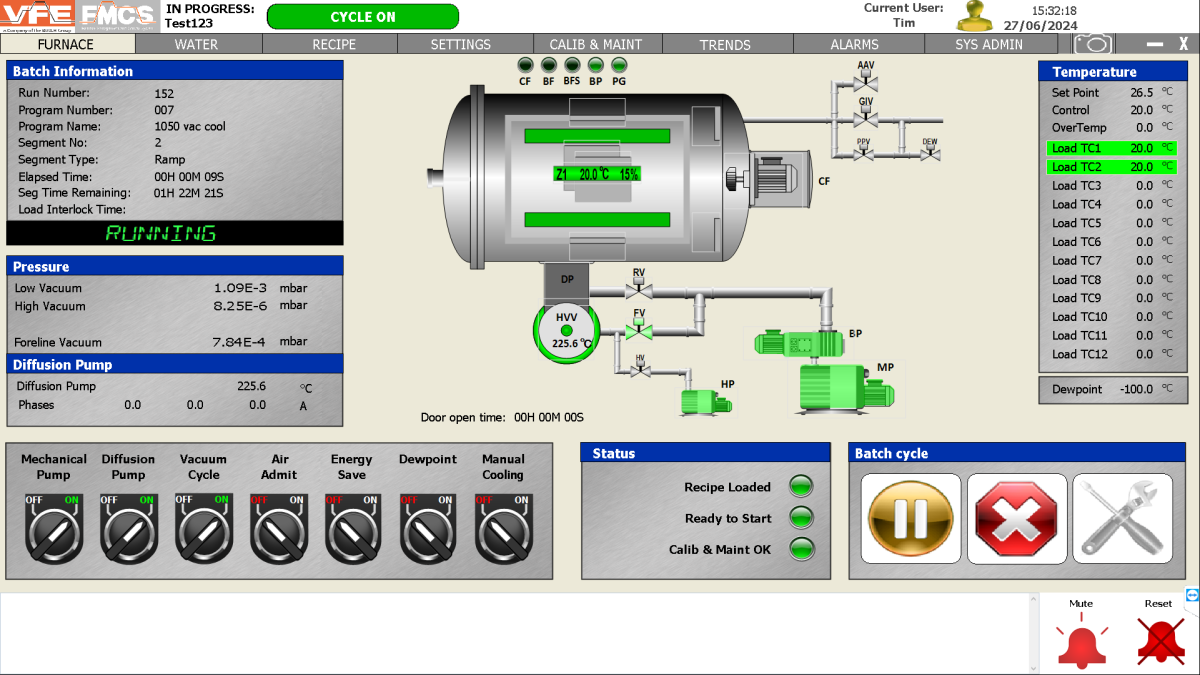

The controls and instrumentation of vacuum furnaces are critical design features that ensures the process conditions meet strict requirements, whether it involves producing compliant aerospace parts or pushing the boundaries of furnace capability to develop new brazes.

The diversity of the furnace instrumentation and controls package needs to be tailored to suit the application and quality control requirements, whether it is controlling various temperature set points, removing volatile contaminants using vacuum, or preventing the vaporization of elements within the material.

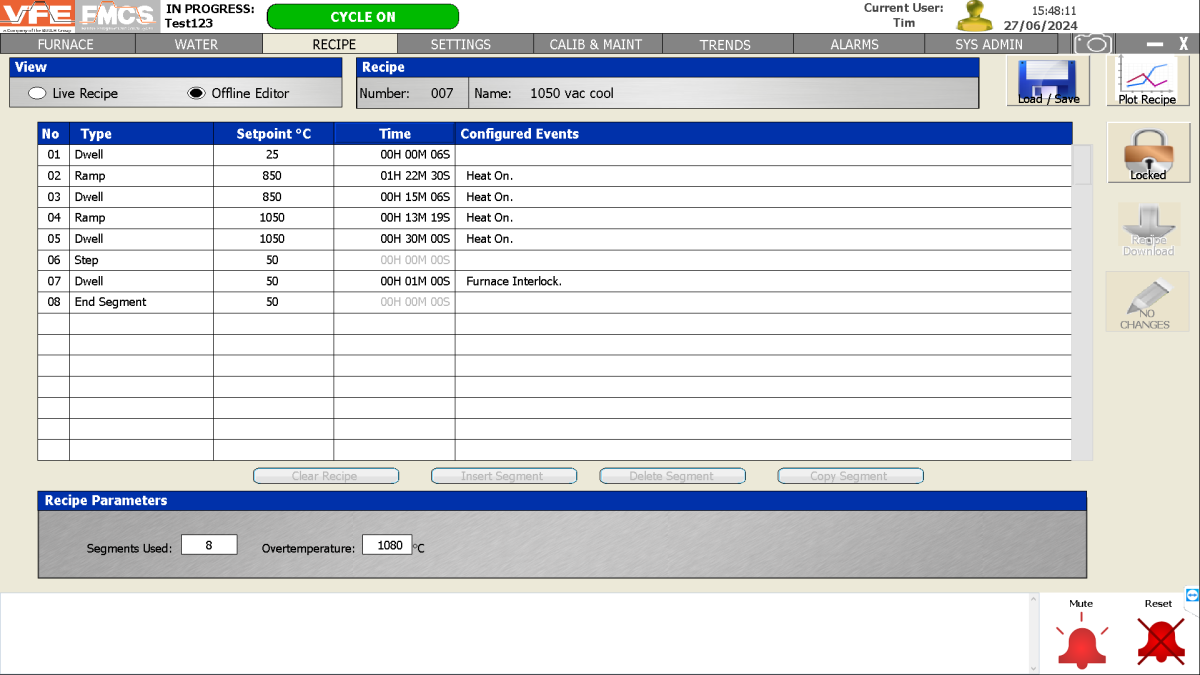

Modern digital vacuum furnace control systems serve as primary user interfaces for operators and engineers, providing a high level of supervision over the system and process. These systems offer various control features:

- Simple yet powerful graphical profile editor.

- Monitoring and issuing of process commands, such as controller setpoint changes.

- Displaying current running status with numerical and graphical presentation.

- Allowing manual intervention by authorized users.

- Displaying system alarms and diagnostic data.

- Recording all process data and user actions in a secure database.

- Providing the ability to search the database and view, print, or export historical records.

- Ability to connect to a network or production management system.

These features enable operators to optimize furnace performance and enhance overall equipment effectiveness (OEE).

In critical applications like brazing aerospace components, adherence to quality standards is paramount. One such standard, AMS2750, sets stringent requirements for vacuum furnace operations. While originally designed for aerospace applications, AMS2750 has become a benchmark for quality in various industries.

AMS2750 outlines pyrometric requirements for equipment used in the thermal processing of metallic materials. It significantly impacts control system design and covers various aspects, including:

- Temperature sensors

- Instrumentation

- Thermal processing equipment

- System accuracy tests (SAT)

- Temperature uniformity surveys (TUS)

- Reporting

- Quality assurance provision

Compliance with AMS2750 ensures that vacuum furnace operations meet the highest quality standards, particularly in critical industries where precision and reliability are essential.

Conclusion

Vacuum brazing offers unparalleled advantages in producing strong, reliable joints across various industries. As technology continues to evolve, the role of vacuum brazing in achieving precision engineering solutions will only grow. With careful attention to process control and quality assurance, vacuum brazing remains a cornerstone of modern manufacturing, enabling the creation of advanced products for many critical applications.

Optimize your furnace’s performance and ensure AMS2750 compliance with our advanced control system upgrades, precision calibration, and Temperature Uniformity Surveys (TUS).

Book a consultation